How is the pharma supply chain different from the classic model?

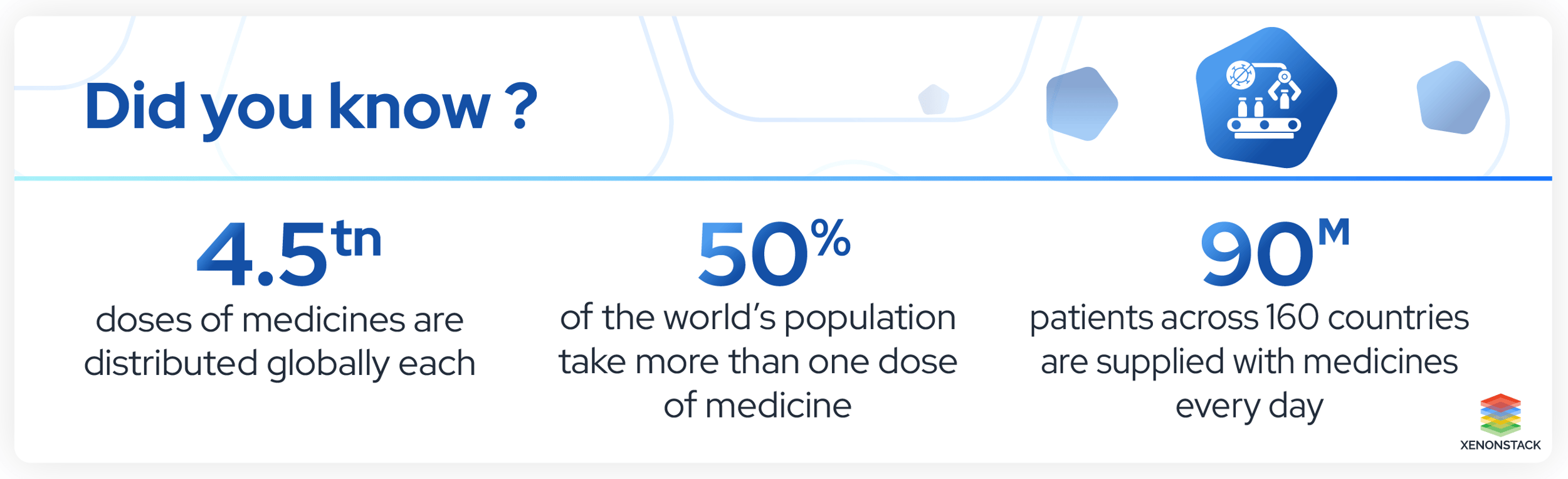

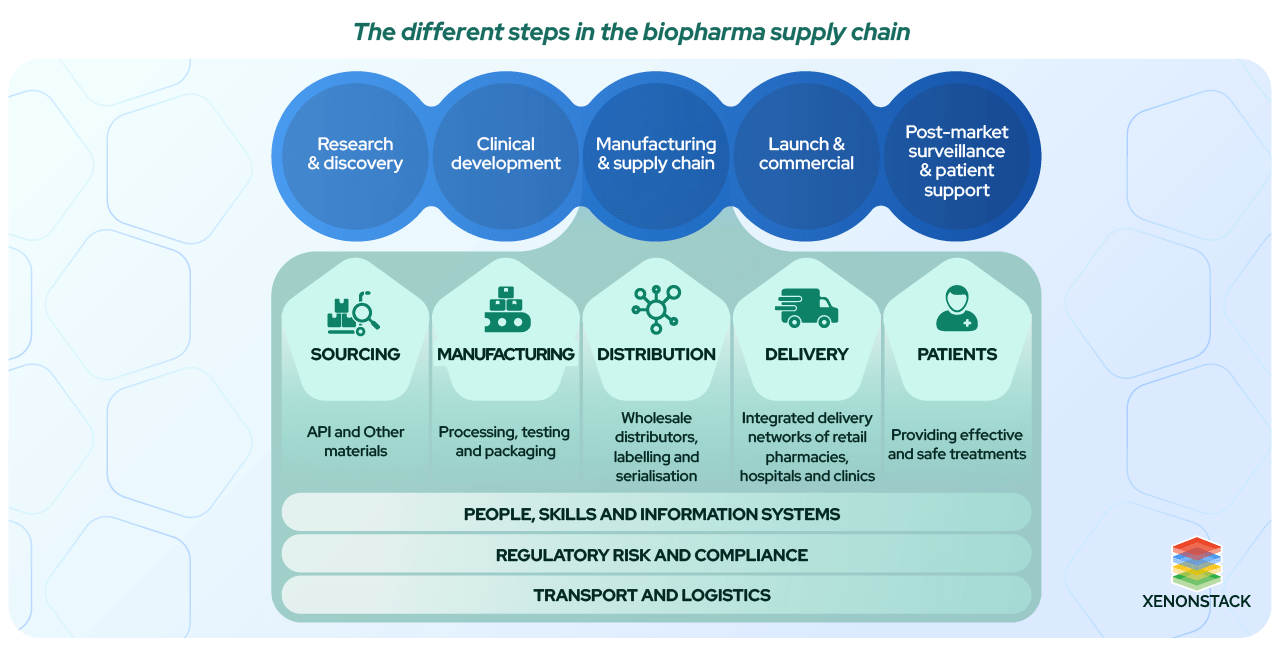

The biopharmaceutical supply chain is a complex process that involves several steps, from sourcing and supplying materials to manufacturing, distribution, and finally, delivering the biopharmaceutical to the consumer. This process is crucial in connecting the discovery of new therapies to the patients who need them. It forms a golden thread that links the entire process together.

The biopharmaceutical industry faces various challenges and opportunities when managing its supply chain. This requires a departure from traditional approaches. The following are some of the critical aspects to considerChallenges faced by Biopharmaceutical Companies

Logistics and Risk Management Challenges:

1. Cold Chain Logistics: Navigating the complexities of the cold supply chain for pharmaceuticals with specific temperature requirements can pose significant logistical challenges. For example, maintaining ultra-low temperatures like -94°F for certain products, such as COVID-19 vaccines, is critical to ensure their efficacy and safety.

2. Financial Losses: Significant financial losses, with pharma companies losing over $35 billion in 2021 due to product spoilage within cold supply chains.

3. Demand Management: Inability to manage incredible peak or demand troughs, leading to challenges like Biopharmaceutical shortages or oversupply.

4. Biopharmaceutical Integrity Assurance: Absence of robust processes to ensure the integrity of Biopharmaceuticals during transportation, storage, and distribution.

5. Transparency Issues: Lack of transparency into several supply chain links hinders effective tracking and monitoring of pharmaceutical products.

6. Environmental Impact: The absence of mechanisms to examine environmental footprints or address issues related to medical waste contributes to sustainability challenges.

Operational Challenges:

1. Product Portfolio Complexity

Managing a diverse product portfolio with varying formulations and production processes can add complexity to supply chain management.

2. Demand Variability

Fluctuating Demand: Coping with inherent variability in demand for biopharmaceutical products, leading to challenges in production planning and inventory management.

3. Regulatory Stringency

Stringent regulatory standards must be followed, with compliance requirements and extensive documentation throughout the supply chain.

How AI can augment supply chain transformation?

Much data is generated throughout the biopharma supply chain, but it has traditionally been underutilized. Utilizing AI to process this data will support real-time decision-making, enhance operational efficiency, and ultimately create a cost-effective, almost autonomous, and thriving supply chain. Xenonstack has identified some critical areas and processes in the supply chain where AI will likely have the most significant impact.

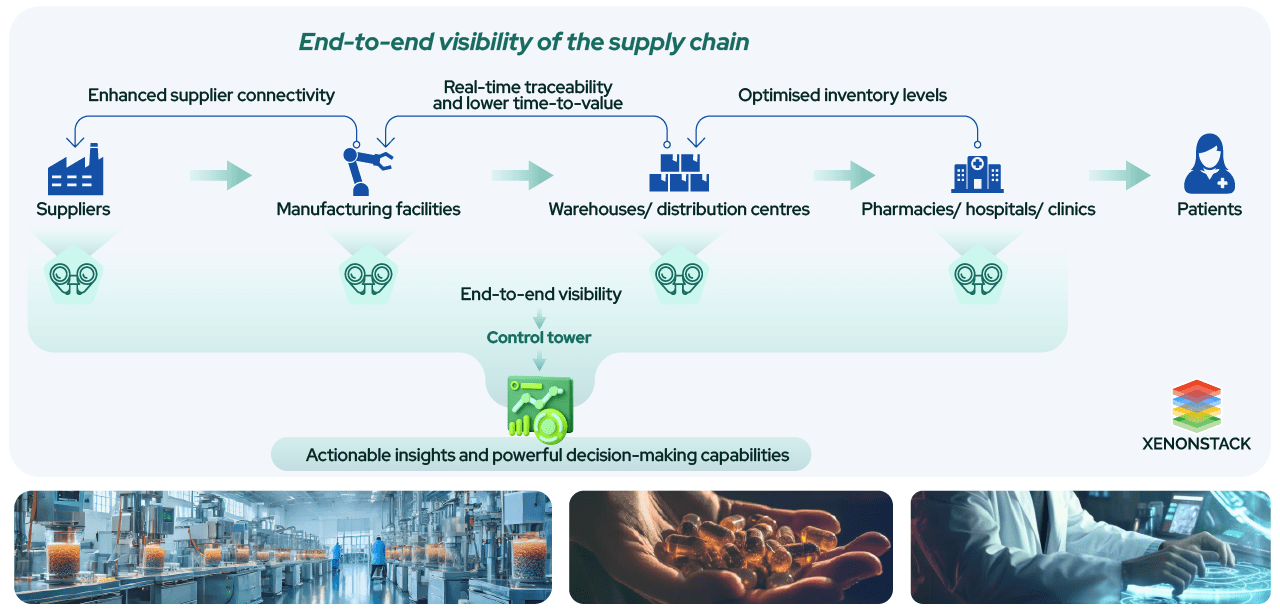

1. End-to-end visibility

"Supply chain visibility" refers to accessing data related to all transactions and demand triggers throughout the supply chain, including every step, tier, and logistics movement. This concept can be achieved through supply chain control towers, which serve as centralized hubs. These towers collect information from various systems for monitoring, auditing, and generating insights.

2. Demand forecasting, inventory management and logistics

Accurately monitoring biopharmaceutical inventory levels is crucial for timely patient access to treatments. Predictive analytics can help track biopharmaceutical conditions and address issues. To avoid shortages and overstocking, pharmaceutical companies can use machine learning models to predict demand based on historical data, market trends, and consumer behavior. This can revolutionize the industry and ensure patients receive timely access to needed treatments.

3. Optimising predictive maintenance

Pharmaceutical companies need to avoid losing expensive biopharmaceuticals if their equipment malfunctions. However, machine learning-based predictive models can identify the equipment most likely to fail and alert maintenance teams in advance. By leveraging the power of AI-enabled predictive maintenance, these companies can gain insights into equipment performance, forecast results, and minimize business disruptions. This approach enhances operational effectiveness and increases machine uptime, enabling companies to focus on their core competencies confidently.

4. Cold chain management

ML models can work together with internet-of-things (IoT) sesors to monitor the temperature of shipped products, detect potential risks, and alert the driver if needed.

5. Route optimization

Riders want the shortest and most efficient route from their Uber driver. Similarly, sensitive pharmaceuticals can benefit from machine learning models' power to select the most efficient route and combine that data with other factors like weather or road closures. This could reduce the time of biopharmaceutical transportation by hours or even days.

6. Warehouse automation

Integrating AI into warehouse automation tools can speed up communications and reduce errors in "pick and pack" settings. At its simplest, AI can predict which items will be stored for the longest time and position them accordingly. Using this approach, Lineage Logistics, a cold-chain food supplier, increased productivity by 20%. Another example of AI in action is placing high-volume items to make them easily accessible while reducing congestion.

7. Identifying and eliminating counterfeit Biopharmaceuticals

The World Health Organization (WHO) reported that one in 10 biopharmaceuticals in developing countries are counterfeit. ML models combined with big data and IoT sensors can help identify these products in real-time.

Roadmap for implementing an intelligent Supply Chain

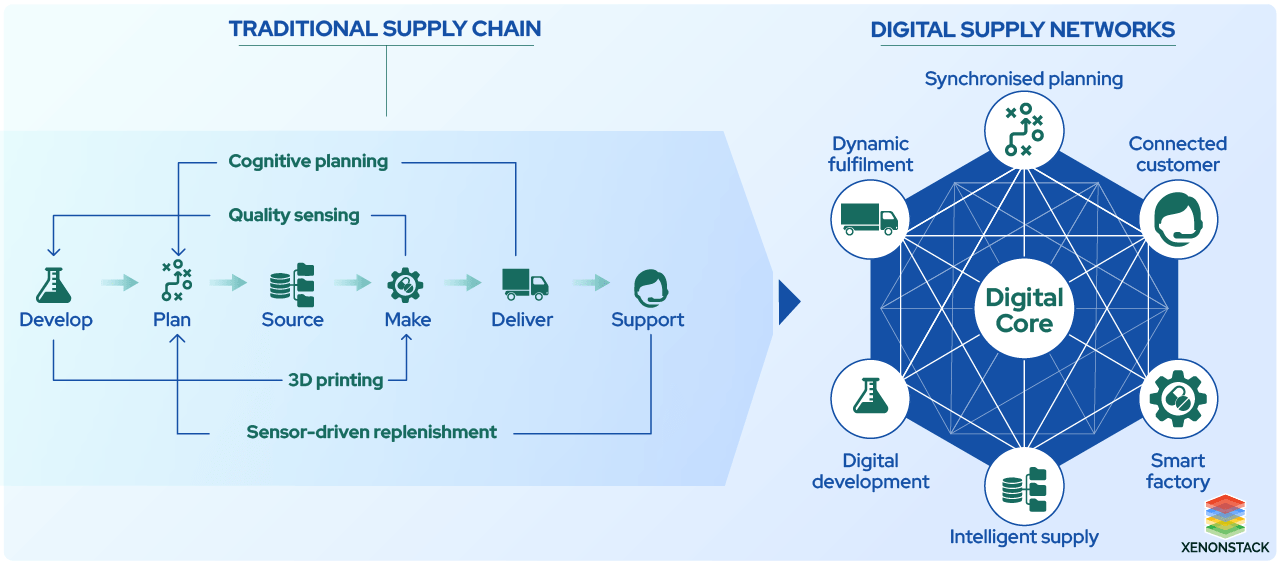

Over the next few years, implementing AI technology will revolutionize how industries operate. However, this process requires strategic thinking and time as it significantly shifts from traditional linear supply chains to dynamic, interconnected, and open digital supply networks (DSNs) that are AI-enabled.

The approach of manufacturers in various industries to integrate digital technologies involves distinct stages

1. Begin with Small: Demonstrate the Value with Pilot Projects

Identify and prioritize small pilot projects to showcase the quick wins of AI-enabled solutions. This will help build confidence and secure buy-in from stakeholders.

2. Expand Quickly: Implement Across the Entire Supply Chain

After a successful pilot project, expand implementation across the biopharma supply chain. Learn from previous experience to optimize efficiency and effectiveness.

3. Think Big: Value-Driven Innovation Throughout the Entire Supply Chain

It is essential to apply a value-driven approach for innovation across the entire supply chain to achieve a holistic transformation and unlock significant benefits.

The future of AI-enabled Supply Chains

AI technology can significantly benefit the life sciences industry by moving beyond the accumulation of large amounts of data and towards actionable insights. Biopharma companies should adopt advanced digital solutions to unlock their potential and meet future demand for more precise and personalized therapeutics. A shift from traditional linear supply chains to AI-enabled, interconnected DSNs with radically interoperable data is necessary to achieve this. As a result of the COVID-19 pandemic, we anticipate that the digital transformation of the supply chain will accelerate at an unprecedented rate and scale.

- Read more about : Supply Chain Management System Benefits and Solution

- Explore more about : Blockchain in Supply Chain Management

.webp?width=1921&height=622&name=usecase-banner%20(1).webp)