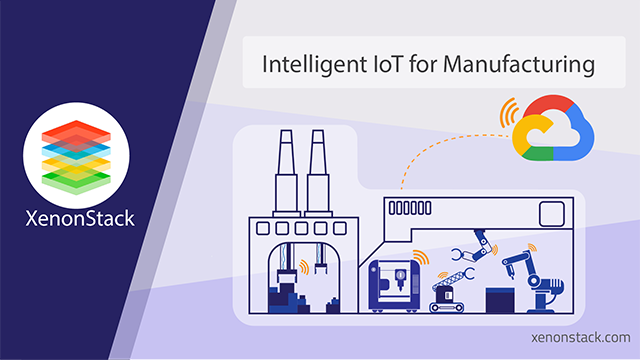

Introduction to Smart Manufacturing

Smart manufacturing is a technology-driven approach that uses Internet-connected machinery to observe the production process. The purpose of Smart Manufacturing is to recognize the possibilities for automating processes and use data analytics to enhance manufacturing execution.- Machines have threshold values for the different parameters like Temperature, Oil pressure, and Amperage which should not be crossed.

- Implementation of Internet of Things (IoT) enables proactive maintenance break on the machines to enable manufacturing for smart manufacturing. Collection of data in Real-Time is an excellent solution.

- Smart Manufacturing industries reduce the risks

Challenge for Building the IoT Platform

Scalable Solution for smart manufacturing to manage all the machines at a single central point and handle sizeable Real-Time streaming data from sensors that can provide the alerts and trigger to turn off the motor in very minimum time.

Solution Offered Real-Time Data and IoT Platform

Installation of the sensor to collect each value (Temperature, Oil pressure, Amperage) in Real-Time using Google Cloud Platform. Google Cloud IoT Core to ingest data from all sensor attached to different machines. The data collected from the sensors contain the machine identification number to differentiate the received data. Click here to know more about IoT Analytics Platform for Real-Time Data Ingestion

Google Cloud IoT Core sends the collected data to Google Cloud Pub/Sub. This data stream routes at multiple locations. Store the raw data into BigQuery and also to Google Cloud Function. Detect whether the collected data values are higher than the threshold values. Implement Google Cloud Function and Google Pub/Sub as the trigger. Google Cloud function is an event-driven serverless compute platform to deploy Function As a Service which is auto scalable, highly available and fault tolerant.

Cloud function triggers the configuration changes to the Google Cloud IoT Core if data values are higher than the threshold value, for another sensor which controls the motor of the machine. Google Cloud IoT Core sends the trigger to the device to turn off the machine and have a maintenance break.

Technology Stack

- Google Pub/Sub

- Google IoT Core

- Google Cloud Function

- Google Cloud DataFlow

Technical faults in machinery will decrease turbines' productivity, disrupt deliverables, and ultimately decrease credibility. IOT ( Internet of Things) in Manufacturing Industries is necessary.

Understanding Predictive Maintenance Techniques

Predictive Maintenance attributes to an inquisition of an application to repress deterioration. It comprises of maintenance, monitoring, data analysis, Intelligence, communication and pre-warning signals for an event occurrence.

Steps of Predictive Maintenance -

- Collection of Data

- Data Analysis

- Monitoring

- Predictive Analysis

Predictions can be Batch Processing or Real- Time. Predictive Analytics combined with IoT and Google Cloud Platform results in numerous magnificent Real-Time Applications. IoT stores abundance of data to produce Machine learning applications using Artificial Intelligence and Predictive Analytics.

Influencing to Real-Time streaming of data, IoT Predictive Maintenance has raised the productivity of applications providing quality and reducing cost, increasing efficiency.

.webp?width=1921&height=622&name=usecase-banner%20(1).webp)